Machine Monitoring Software

Overcome downtime challenges by tracking machine operations in real-time, utilizing advanced OEE, and enhance overall operational efficiency.

Schedule DemoThe Connected Shopfloor

Operational Efficiency

Spot bottlenecks with real time alerts, empower factory teams with customizable dashboards, OEE metrics, and notifications to hit production goals.

Prevent Downtime

Real-time visibility into operations and IIOT-connected machinery across shopfloor, predictive maintenance and spare parts inventory management avoids unplanned downtime.

Data Processing

Process data in real-time, utilizing AL/ML algorithms and analytics to extract actionable insights and optimize machine performance across shopfloor.

Case Study

Global Manufacturers Empowered by iDataOps

In the world of global exports, Radiaant Expovision serves industry giants like Walmart, Zara, and Target. Their business growth revealed challenges from outdated technology, such as no real-time production insights, data integration difficulties, high costs, and spare parts management during downtimes. To address these issues, Radiaant embarked on a transformative journey with Rawcubes iDataOps.

We Achieved

$1M year on year savings with services and product engagement.

30% increase in throughput/uptime with real-time visibility across the factory floor.

80% of manual data analysis was reduced with lower dependency on data teams.

Real Time Insights

Advanced OEE

Chart for machine uptime and downtime

Conduct a thorough OEE analysis, which can be viewed over various time frames

Real-time data on equipment performance

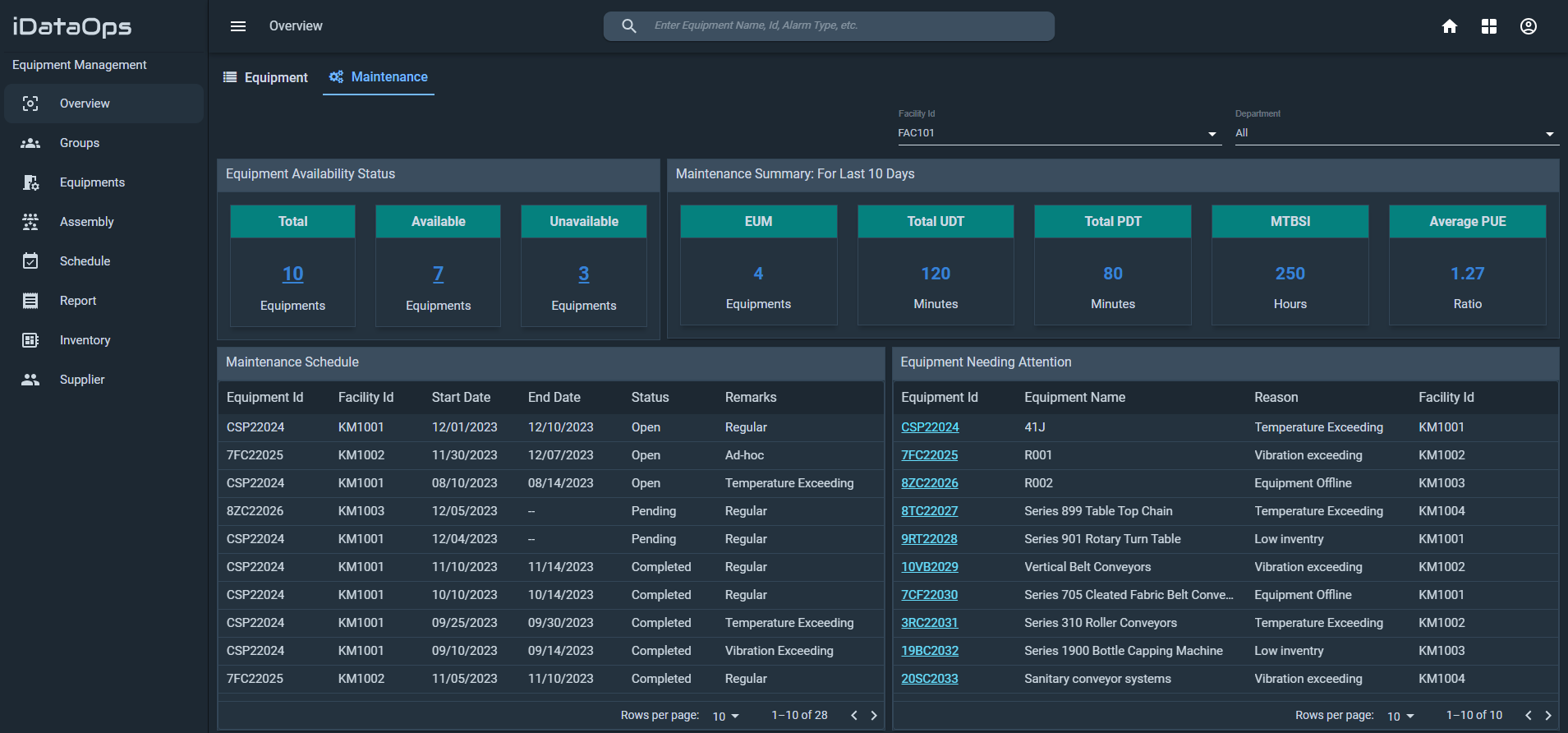

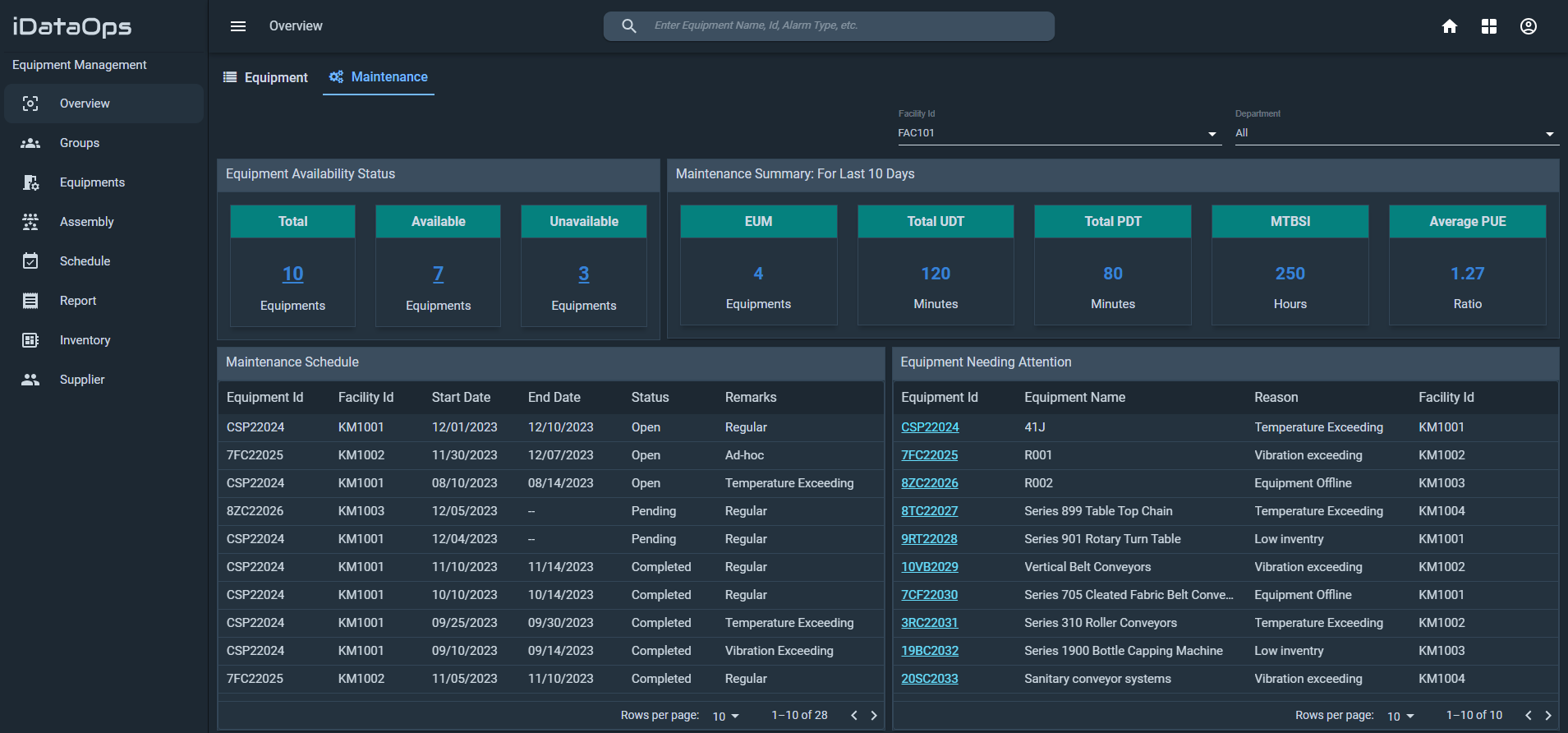

Equipment Management

Equipment Maintenance Management

Seamlessly align data to machine specifications and monitor performance

Add data from the source ERP system seamlessly

Utilize all the details about suppliers, category, part list, lead time, rating and service area in one place

Trusted By Manufacturers

Eliminate Uncertainty, Maximize Performance

Ready to unearth new trends, bridge the gap between modern and legacy machines, eliminate downtime, and automate your maintenance workflows? Experience the difference of Rawcubes iDataOps firsthand by reserving a complimentary demo today.

Book Demo