Real-Time Machine Monitoring

Optimize costly downtime with predictive machine maintenance, advanced OEE, and real-time data integration capabilities with iDataOps

Schedule Demo

Automated Machine Monitoring, Predictive Maintenance and Advanced OEE

Embrace the future of manufacturing by harnessing data from your machines and systems with an easy-to-use machine monitoring software. With iDataOps, you gain the ability to make decisions by leveraging turn-key predictive machine analytics solutions without the need for cumbersome data integrations.

Connect Any Machine

Establish connections, gather, and display data from any machinery present on the manufacturing floor.

Overall Equipment Efficiency

Ensure optimal equipment utilization, minimal downtime, peak performance, and superior product quality.

Predictive Maintenance

Stay steps ahead and anticipate potential issues before they disrupt production, and maximize the lifespan of your equipment.

iDataOps Features

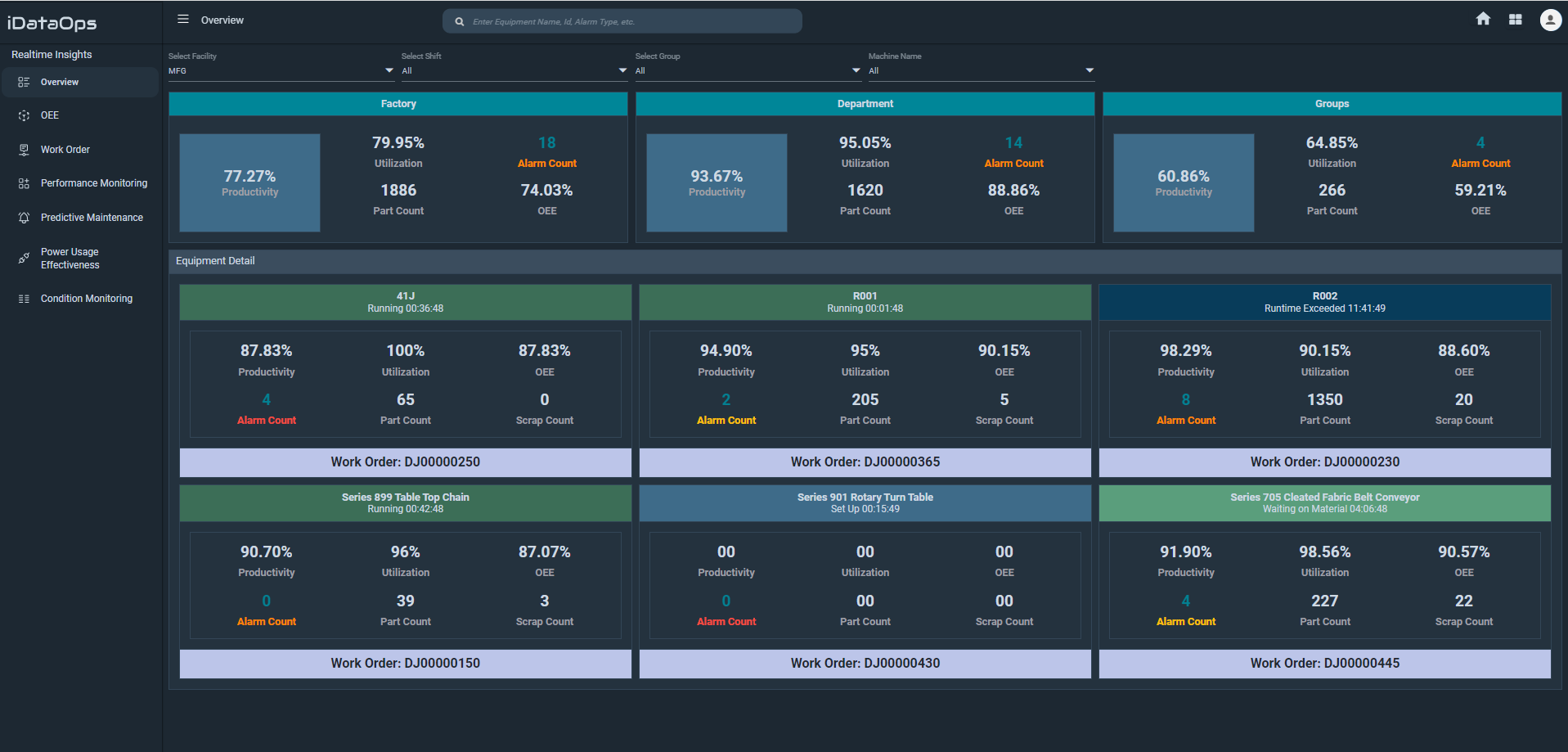

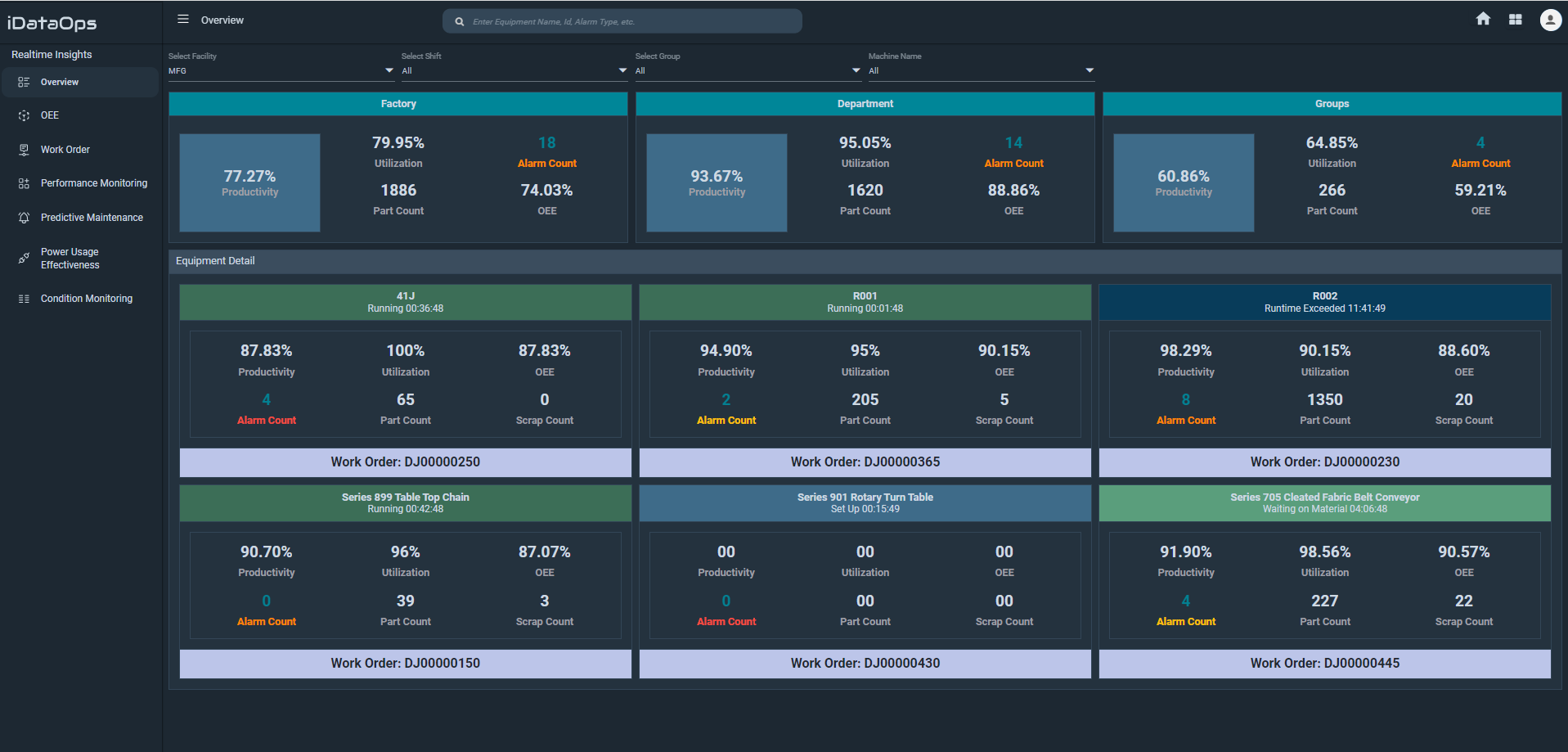

Centralized Command Center

- A centralized dashboard to oversee real-time visibility of key metrics for all your machinery and production processes, productivity, and resource utilization.

- Overview of alerts and notifications for the facility.

- Factory and department-wise view, select the line, grouping based on the production line.

- Effective control and monitoring of equipment per facility, per operator, group, shift, and machine name.

- Machine's efficiency directly affects scrap count, influencing overall quality.

Advanced OEE

- Chart for machine uptime and downtime and calculate the Overall Equipment Effectiveness (OEE).

- Conduct a thorough OEE analysis, which can be viewed over various time frames, including months, days, hours, and even down to 60-minute intervals.

- Provides real-time data on equipment performance, allowing for immediate intervention and adjustments to prevent issues from escalating.

- Compare the performance of different equipment or production lines, enabling management to focus on areas that require the most attention and investment.

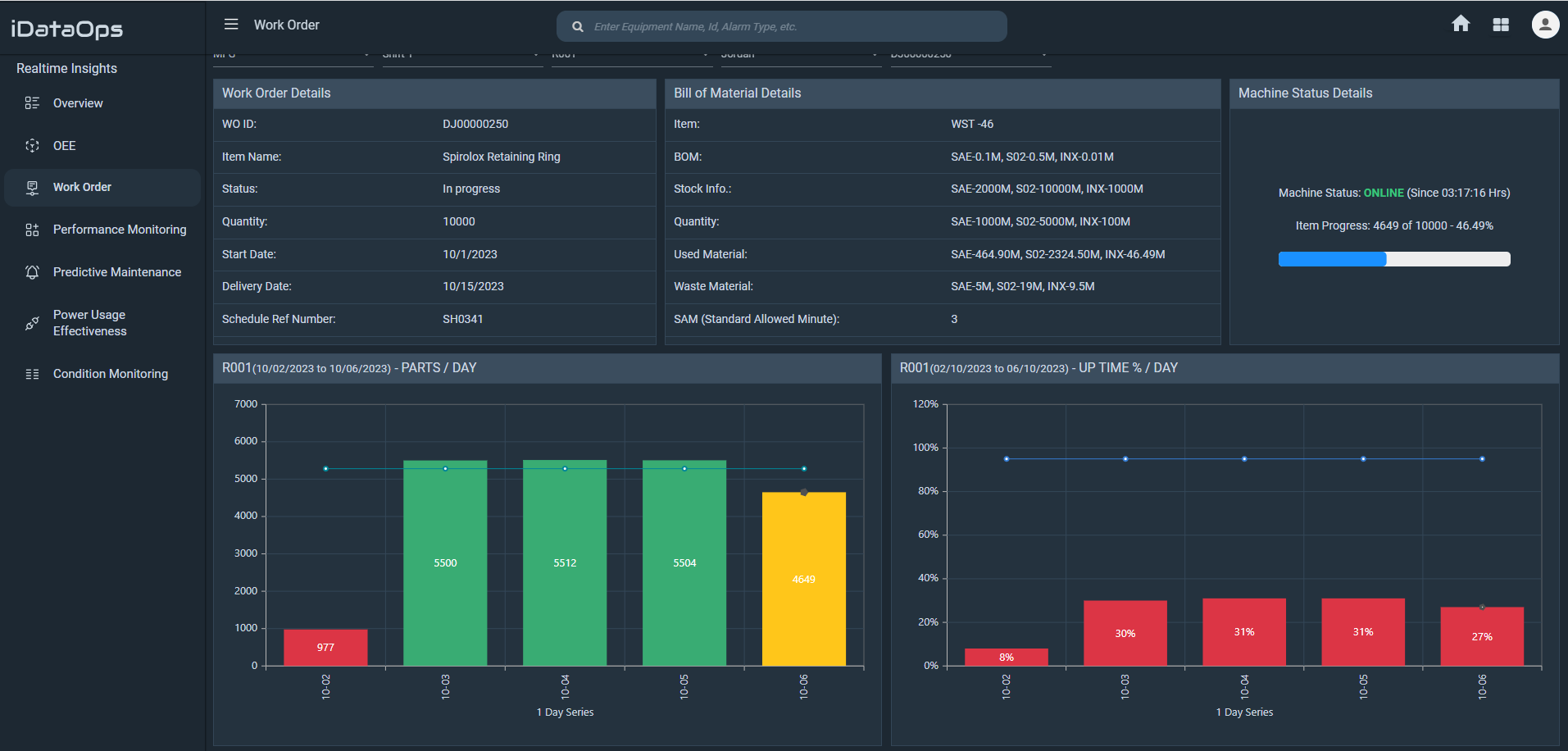

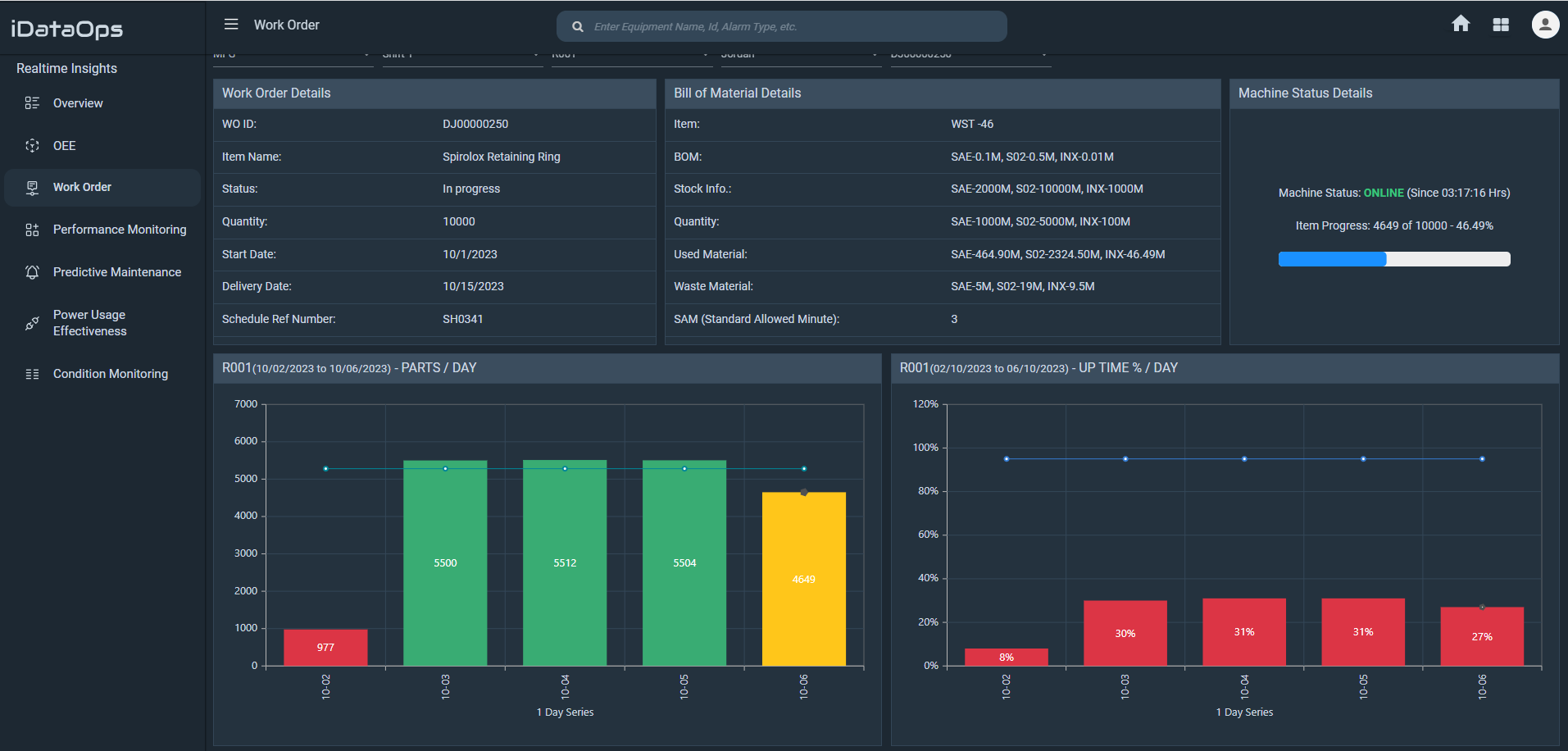

Work Order Management

- Integrate with existing ERP system and the work order management system for accurate data tracking, analytics, and utilization.

- Conduct in-depth analyses for specific work orders, determining factors such as OEE and work order variability compared to planned time.

- We can track production throughput, OEE, and daily throughput targets at the work order level to enhance decision-making.

- Production teams can swiftly identify and keep track of any anomalies or downtimes.

- If any irregularities occur during the day, assess whether there was downtime or any other anomalies by examining work orders.

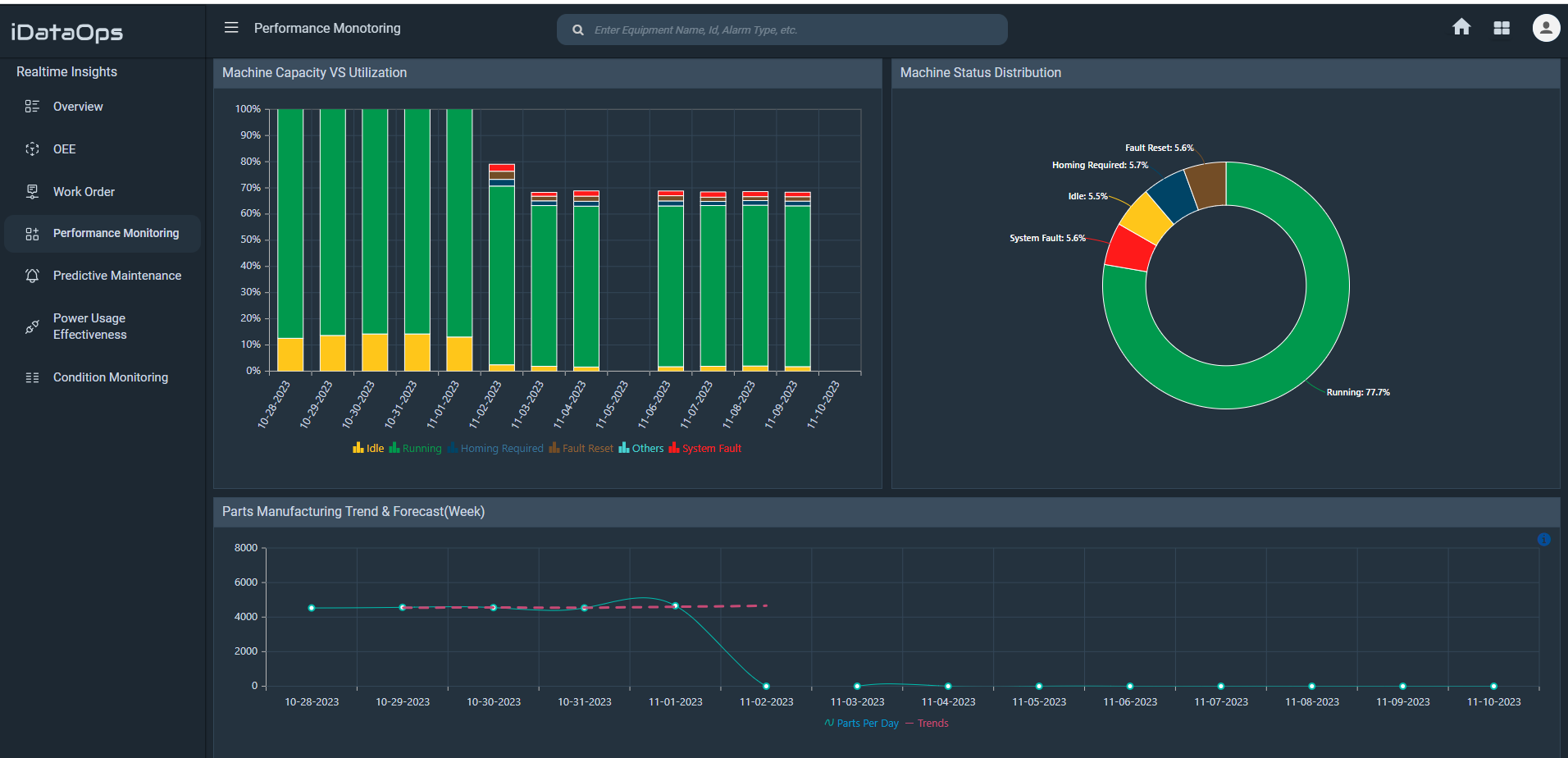

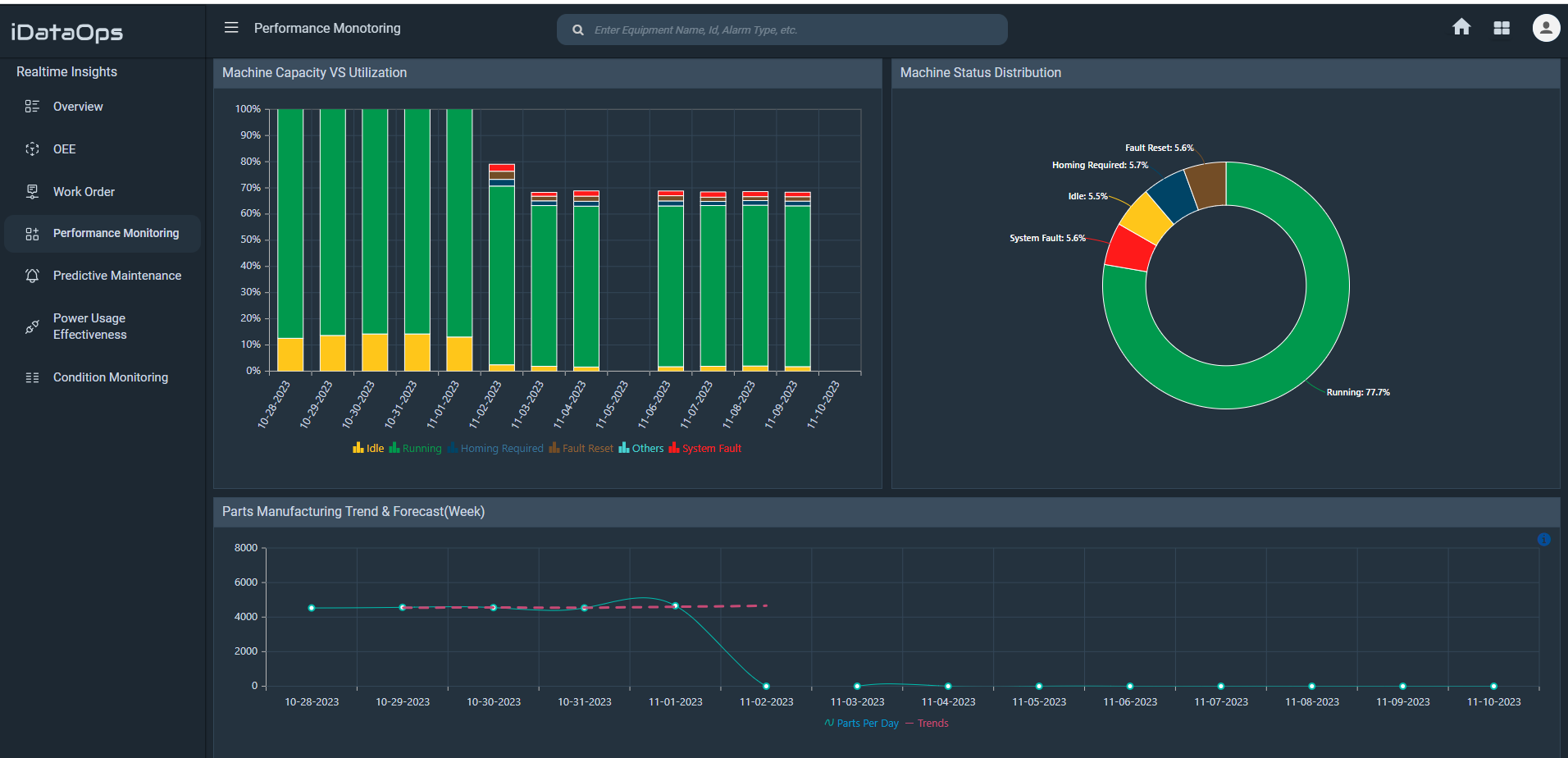

Machine Performance Monitoring

- Utilize AI & ML algorithms to make predictions.

- Leverages historical and real-time data for accurate forecasts.

- Proactive scheduling optimizes resource allocation and enhances efficiency by allowing organizations to plan production activities in advance.

- Empowers organizations to make well-informed decisions, reducing production risks, timely delivery.

Predictive Maintenance

- Predictive Remaining useful life (RUL) and mean time to failure (MTTF).

- Prioritize maintenance or replacement efforts on components with shorter RULs, ensuring the most critical assets are addressed first.

- Production process optimization based on asset condition.

- Support through data scientist to uncover custom opportunities.

Power Usage Effectiveness

- Display of the machine's monthly, weekly, and daily load distribution in showing peak usage times and idle periods.

- Leverage a breakdown of energy consumption for the machines, to pinpoint which equipment may need maintenance.

- Real-time alerts for significant load variances, enabling maintenance teams to investigate, rectify issues and help in maintaining ESG levels.

Condition Monitoring

- Monitor equipment performance and analyze data, to identify when machines are experiencing wear and tear, and overheating for proactive replacement before they fail and cause unexpected downtime.

- Excessive vibration accelerates equipment wear and early failure. Our predictive maintenance tool monitors vibrations, spotting irregular patterns for early detection and prompt corrective action.

- Streamline the process of monitoring equipment and utilize real-time insights for improved decision-making for improved production.

Eliminate Uncertainty, Maximize Performance

Ready to unearth new trends, bridge the gap between modern and legacy machines, eliminate downtime, and automate your maintenance workflows? Experience the difference of Rawcubes iDataOps firsthand by reserving a complimentary demo today.

Book Demo