Digital Manufacturing Acceleration Program

Navigating Operational Gaps to Building a Digital Roadmap

Schedule DemoDecoding Digital Manufacturing Acceleration Program

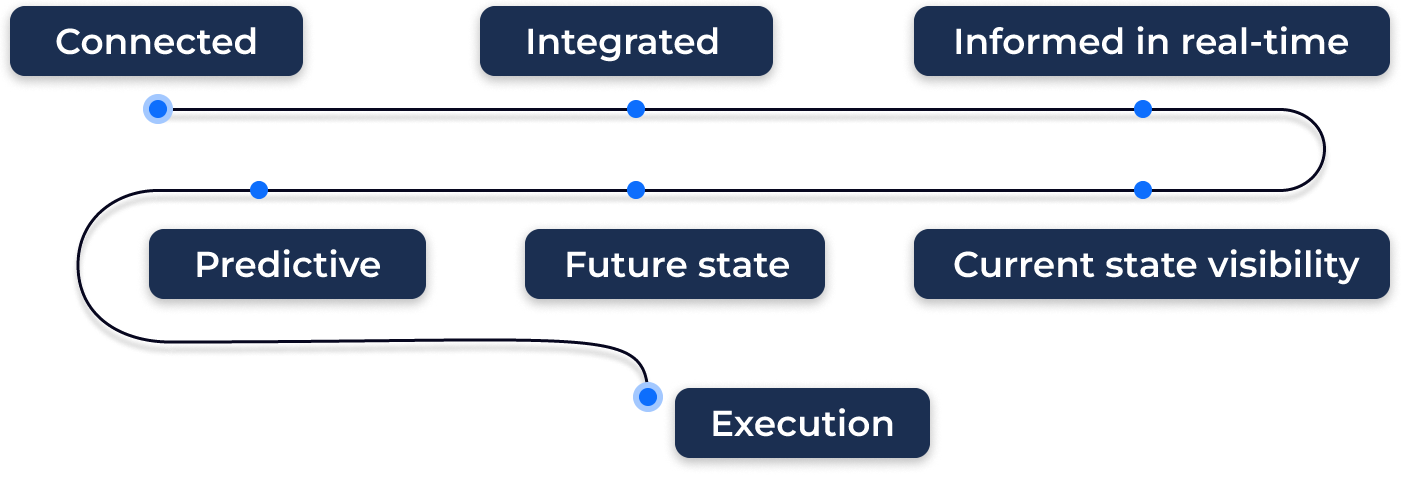

Your Roadmap to Industry 4.0

The DMA (Digital Manufacturing Acceleration) program is designed to assess your current business operations and technology architecture against industry standards and identify operational gaps within your manufacturing processes. We offer proof of value through insights into your production at the machine level, showcasing our value-driven approach. Leveraging Rawcubes' DataOps portfolio and expert team, we focus on boosting operational efficiency and fostering cultural adoption across all levels.

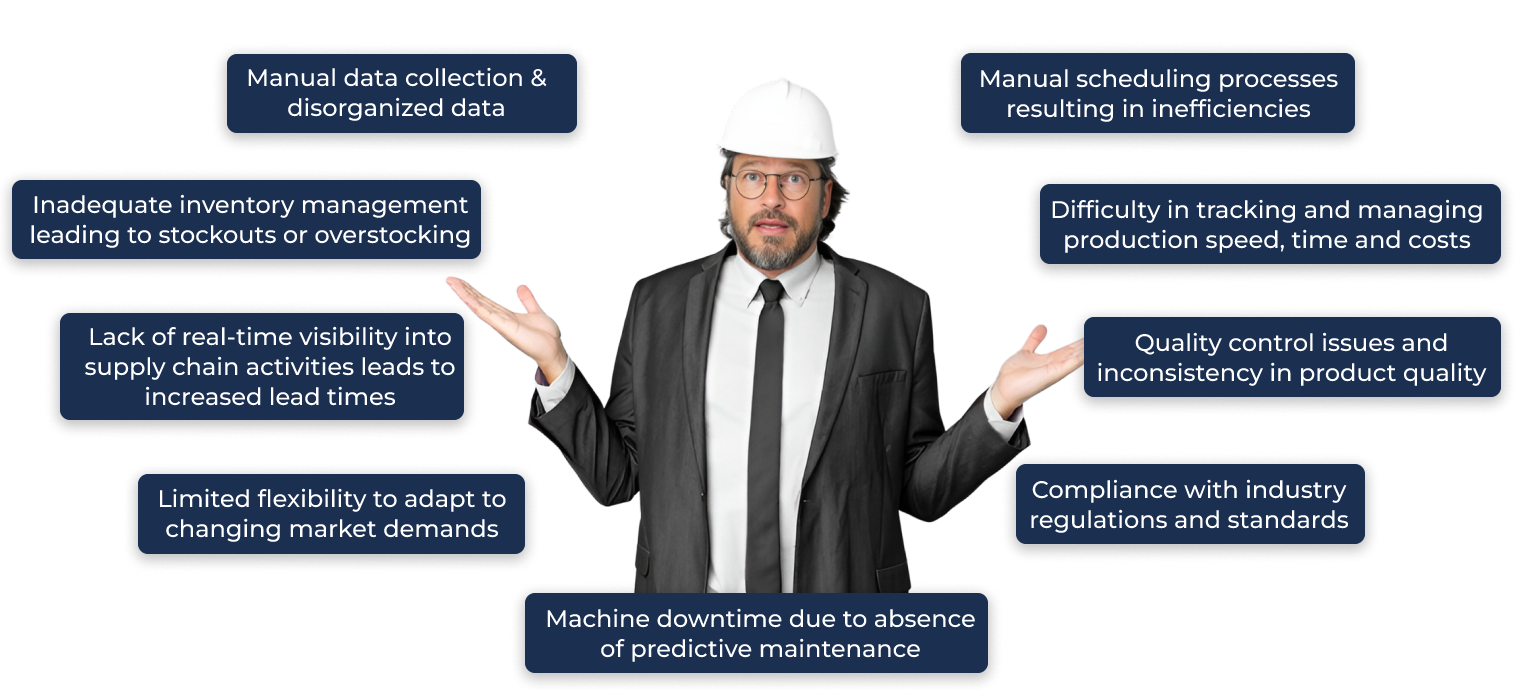

Case StudyWhy Rawcubes Manufacturing Assessment Matters?

Assessment helps manufacturers identify gaps in their traditional manufacturing setup and operational processes such as

How does the DMA Program operate?

Week 1 - DMA Training & Curriculum

This workshop, spanning 4-6 hours, is tailored for manufacturing stakeholders to familiarize them with Industry 4.0 and Lean principles. Through practical demonstrations using iDataOps with demo data, the session will facilitate a deeper understanding of these principles.

Week 2 -3 - Assessment Roadmap and POV

- Assessing business processes.

- Evaluating regulatory and compliance requirements.

- Reviewing the existing data warehouse model and methodologies.

- Evaluating the assets associated with the data warehouse.

- Analyzing the effectiveness of current ETL transformations and integrations.

- Assessing the landscape of SSAS cubes and models.

Proof Of Value (POV)

- Reviewing the functionality and effectiveness of home-grown applications.

- Evaluating their alignment with business needs and requirements.

- Integration of Enterprise Information Systems (EIS).

We demonstrate the POV through the utilization of our distinct capabilities within the iDataOps framework. We engineer a tailored Remote Terminal Unit (RTU) system to align with the specific requirements of the manufacturing environment. Leveraging live data sourced directly from a machine on the shop floor, we provide tangible evidence of our solution's effectiveness.

Our tailored RTUs swiftly collect PLC data, sending it for analysis to provide real-time insights on OEE and production monitoring, capacity vs utilization, predictive maintenance, work order tracking, inventory optimization and more.

What sets us apart?

While others take months, our solution delivers results within weeks.

- Analyzing the business processes supported by dashboards and reports.

- Evaluating regulatory and compliance needs addressed by the tools.

- Assessing the criticality and availability of dashboards and reports.

- Reviewing non-functional requirements such as performance and security.

- Evaluating the application's technology stack, hardware platform, software license portability, database, security, infrastructure configuration, and performance.

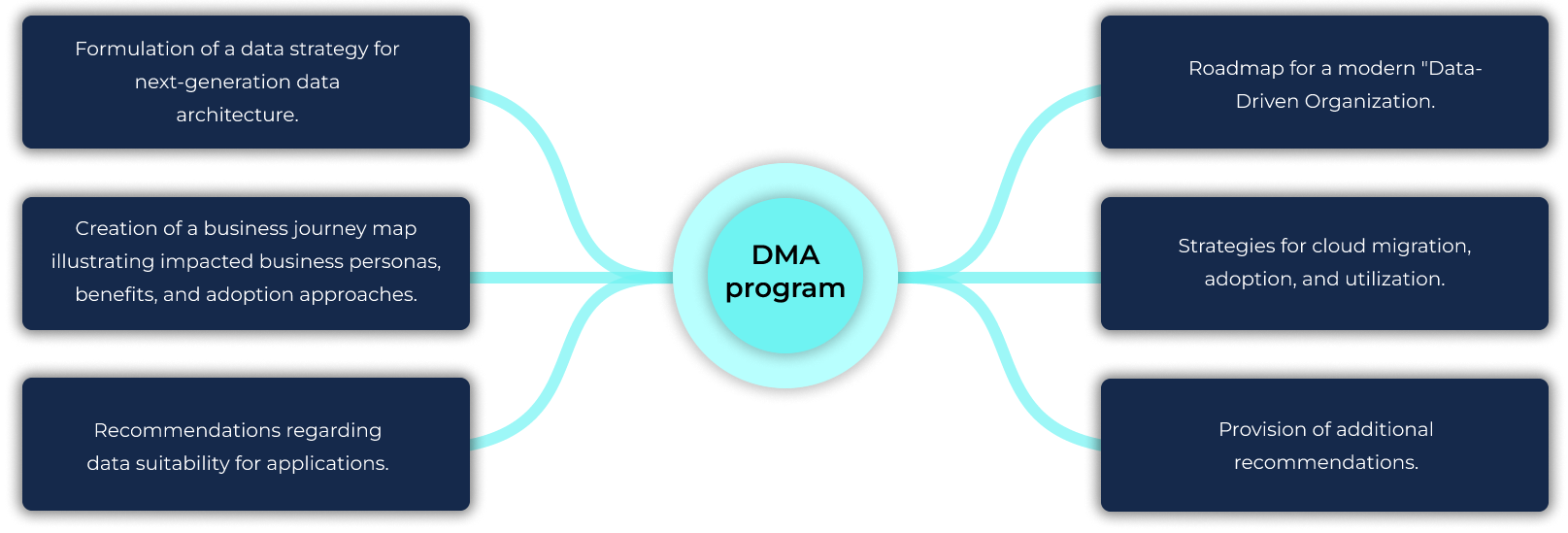

Week 4 - Reports and Data Formulation

Through the DMA program, we deliver a suite of outcomes that significantly advance manufacturing operations

It’s now or never, time for Industry 4.0 with Rawcubes

FAQs

Who is the digital manufacturing program training for?

Our training is suitable for manufacturing organizations of all sizes looking to upgrade their processes.

Is prior experience required for the digital manufacturing acceleration program?

No prior experience is necessary. Our training is designed to cater to participants of all levels of expertise.